Conference publications

HyFiSyn aims to train 13 early stage researchers to become interdisciplinary, multi-talented experts. The 8 universities, 5 industrial partners and 2 professional training organisations offer the researchers a unique opportunity to be trained by world-leading experts in cutting-edge technologies, where they are supported by a strong network and industry participation. The training programme strongly emphasises entrepreneurship and innovation skills to maximise the impact of the project, thereby increasing the EU’s innovation capacity.

If you are interested to obtain a PhD within this project, then please fill out the application form and make sure to include CV, motivational letter and transcripts. For the files to be uploaded, please stick to PDF or Word documents or ZIP-archives thereof. If you have any problem uploading large files, then please send them in a separate email to the project coordinator (yentl.swolfs@kuleuven.be).

Don't forget that you can apply for several positions at the same time by using the tickboxes. If you want to do this, it's best to apply for those positions simultaneously. If you want to use a different cover letter for each position, then please include all of them in a single application.

Conference publications

Improving flexural modulus of interleaved composites using reinforced thermoplastic interleaves

Gokul Ganesh Murali, Paul Robinson, Alexander Bismarck, Christoph Burgstaller

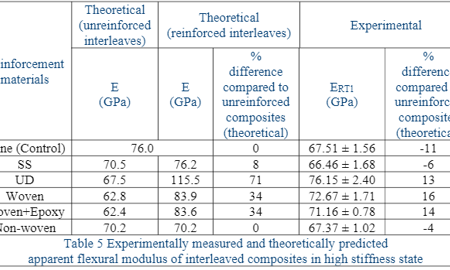

Interleaving the plies of carbon fibre reinforced epoxy composites with thermoplastic interleaves have previously been shown to enable these composites to display controllable stiffness and shape memory properties. However, the incorporation of unreinforced thermoplastic interleaves leads to a decrease in flexural modulus of the interleaved composites. In this study, the flexural modulus of composites with reinforced polystyrene interleaves was investigated. The reinforcements used in this study were: (1) stainless steel mesh (SS), (2) unidirectional carbon fabric (UD), (3) woven carbon fabric, (4) woven carbon fabric with epoxy coating and (5) non-woven short carbon fibre mesh. The flexural moduli of the interleaved composites with reinforced interleaves were predicted theoretically and determined experimentally. Among these composites, significant increases in the flexural modulus were achieved in the interleaves with UD, woven and woven+epoxy reinforcements. Additionally, these interleaved composites were shown to retain their controllable stiffness and shape memory properties.

Design of a deployable composite mesh to form a segment of a circular cylindrical surface

Gokul Ganesh Murali, Paul Robinson, Alexander Bismarck, Christoph Burgstaller

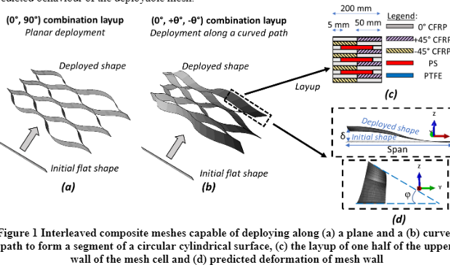

In this work, we have used finite element (FE) modelling to develop an interleaved composite mesh structure capable of deploying along a curved path to form a segment of a circular cylindrical surface. Such mesh structures could allow the creation of semi-permanent deployable shelters for people and vehicles, especially during disaster relief and humanitarian assistance. Abstract can be found in the link below.

Development of intrinsically heated, interleaved composites with controllable flexural stiffness and shape memory capability

Gokul Ganesh Murali, Paul Robinson, Alexander Bismarck, Christoph Burgstaller

Abstract can be found in the link below

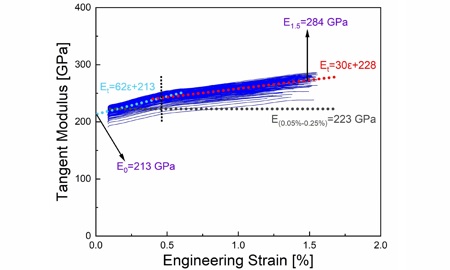

Understanding the mechanical response of glass and carbon fibres: stress-strain analysis and modulus determination

Rajnish Kumar, Lars P Mikkelsen, Hans Lilholt and Bo Madsen

Accurate characterization of fibres is crucial for the understanding the properties and behaviour of fibre-reinforced composite materials. Fibre properties are key parameters for composite design, modelling and analysis. In this study, characterization of mechanical properties of glass and carbon fibres has been performed using a semi-automated single-fibre testing machine. Based on a sample set of 150 glass and carbon fibers fibres, engineering and true stress-strain curves are analyzed. Different modulus determination methods are discussed based on true stress-strain and tangent modulus-strain relationships. For glass fibres, the true stress-strain based tangent modulus is found to be independent of applied strain, whereas for carbon fibres, a tendency of tangent modulus to increase with applied strain is observed. The modulus of glass fibres is found to be independent of fibre diameter, whereas carbon fibres with smaller diameter show higher modulus compared with carbon fibres with larger diameters.